To ensure the success of your decarbonization and CO2 reduction projects, KGK offers comprehensive support in finding optimal solutions for your R&D and production process development.

Our extensive expertise encompasses a range of cutting-edge process technologies that are poised to revolutionize the fields of Perovskite Solar Cells, Electrolyte Membranes and Separators for Electrolysis/Electrolyzers for Green Hydrogen production, and Nano Materials including CNT and CNF.

We specialize in helping you find innovative solutions to enhance the quality of fine particles and slurry, ultimately leading to improved coating accuracies and enhanced performances of end products.

Please contact us if you need solutions for improved dispersion of difficult-to-mix materials, higher productivity or shorter process time.

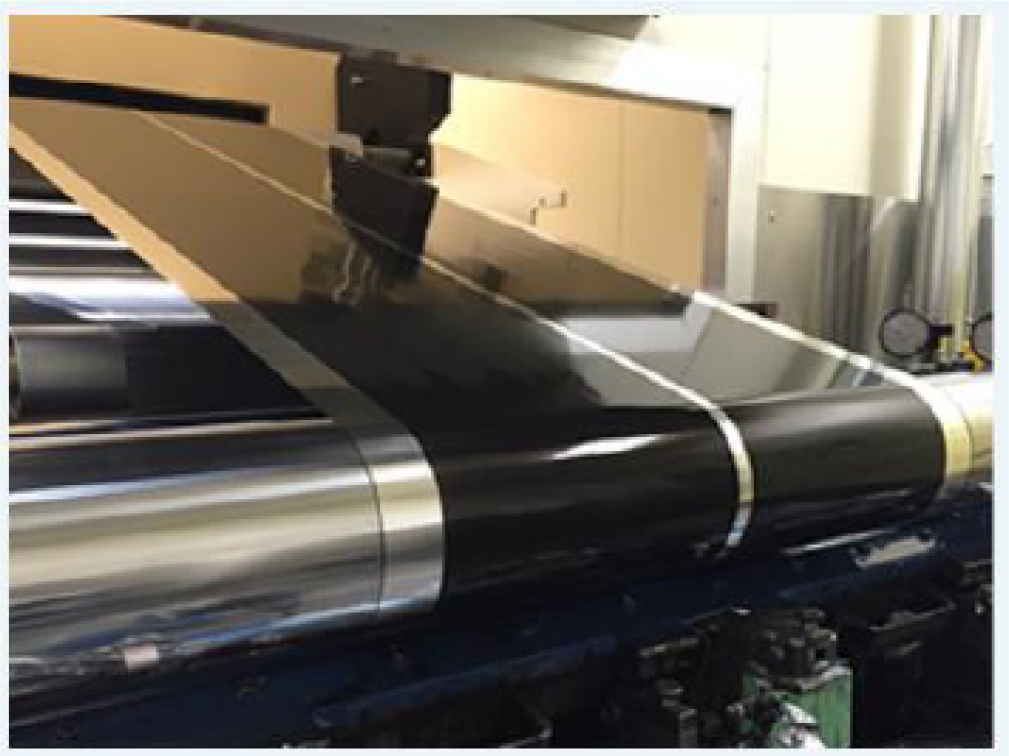

We offer suitable coating system and peripheral equipment from our extensive lineup.

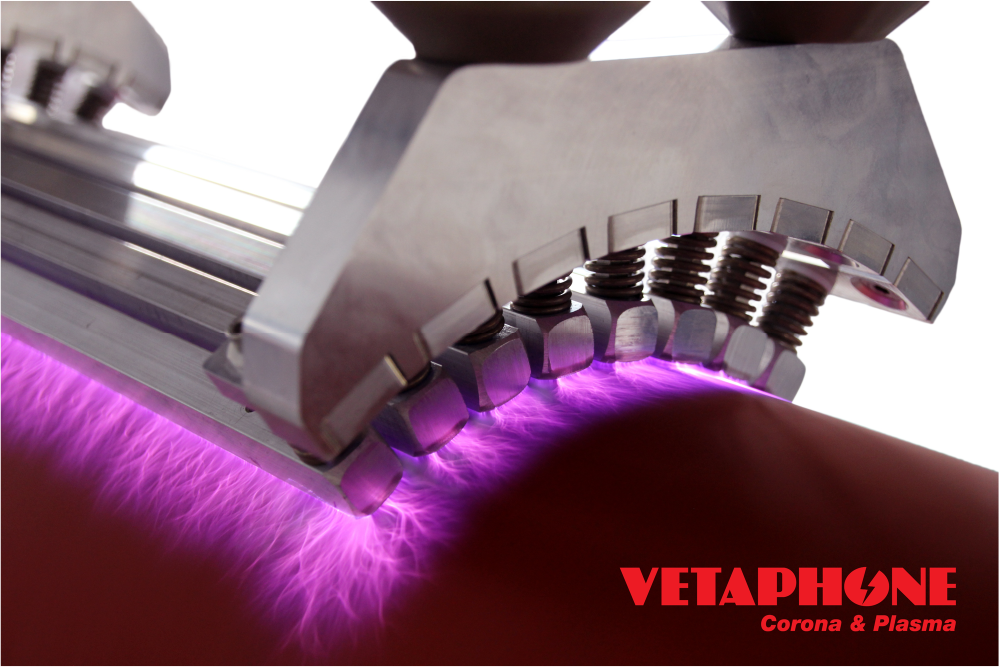

The pioneer of Corona Treatment from Denmark,

Vetaphone boasts 70 years of experience in surface treatment.

A variety of coating methods ; the best coating system for your project is available.

Note : Thickness and accuracy are subject to materials.

Totally-customized drying systems are the best options for your requirements.

Various inspection systems and thickness gauge are optional for your coating systems.

We help you with development and establishment of layer-specific patterning techniques using various types of lasers and methods.