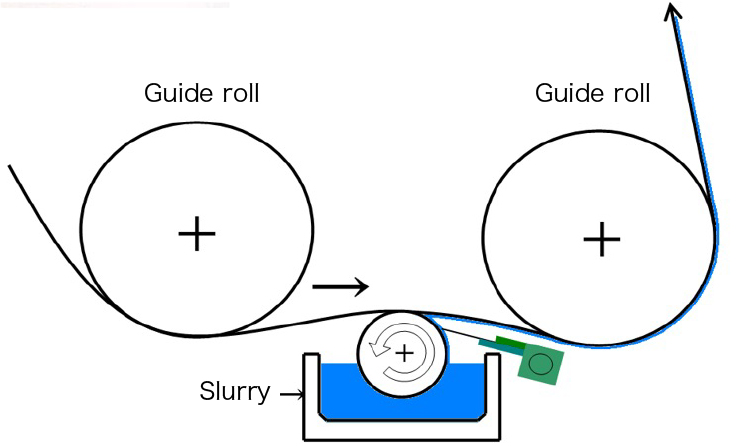

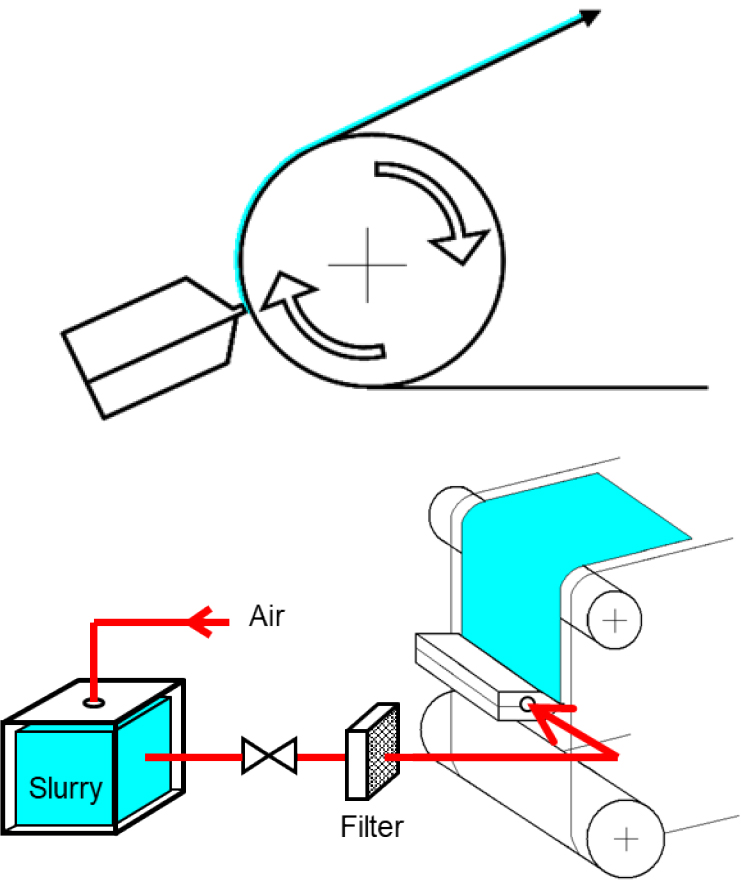

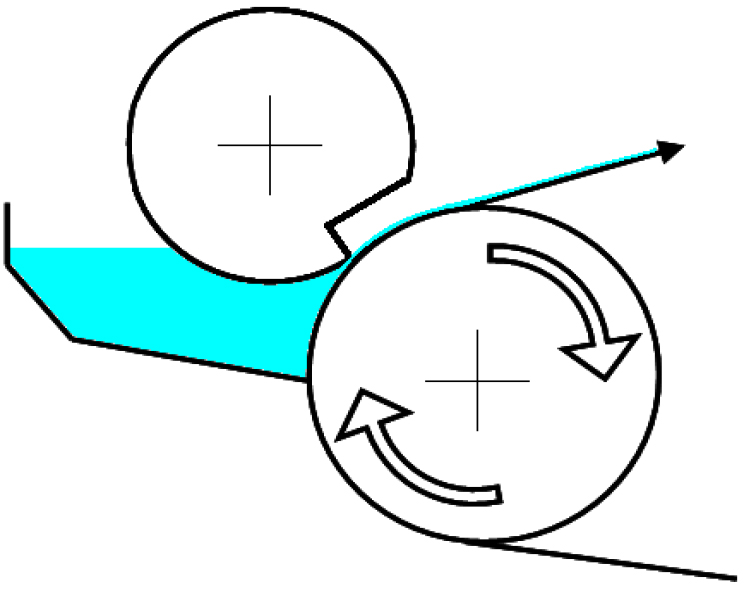

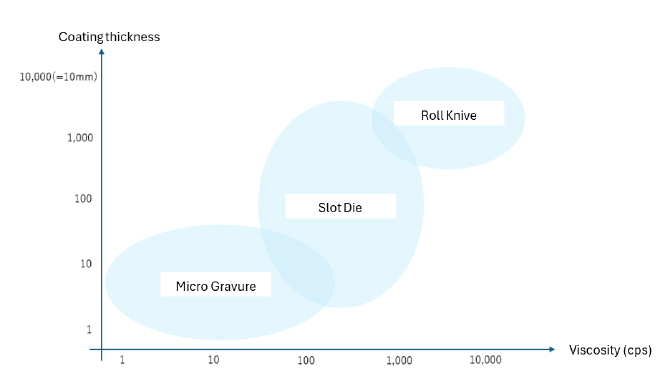

Below are three typical coating methods.

■Micro gravure method

【Advantages】

・Suitable for low viscosity slurry, and it is possible to coat even ultra-low viscosity materials of 50 cps or less.

・The coating results are more stable, due to less wrinkle because of no back roll is used.

・Coating thickness can be changed simply by just changing a gravure mesh and the rotation speed.

・Excellent maintainability (only cleaning gravure roller and liquid pans)

【Disadvantage】

・ It is necessary to pay attention to changes in the state of the slurry due to the open air environment.

Recommend : Over coating onto Positive/Negative electrode. R&D.