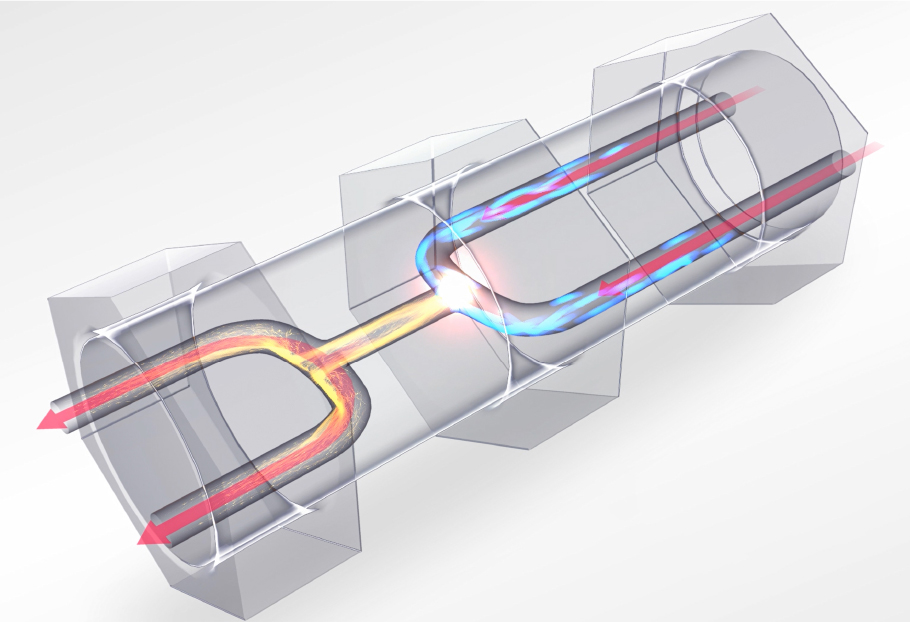

The moment the vacuum bubbles burst or collapse in the liquid, a large shock wave is generated, generating large turbulence in the liquid, causing the particles in the liquid to be torn apart or collide with each other, resulting in atomization.

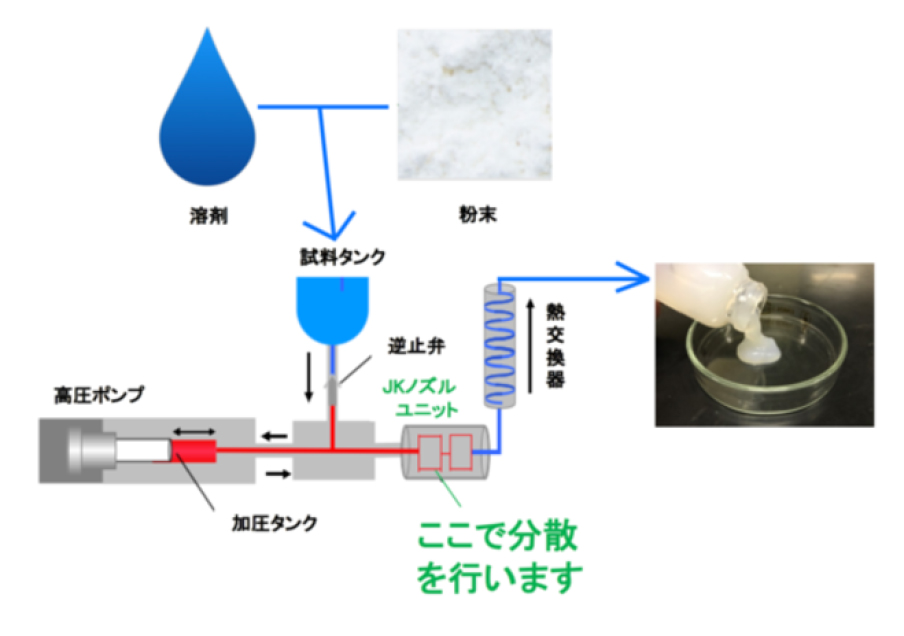

In the nano mixing process, liquids and the particles contained within them are made finer. This makes it harder for the liquid to separate, stabilizing the quality. When making batteries, metal powder is mixed with the liquefied raw materials. By putting the mixture of liquid and metal powder through a high-pressure homogenizer, this make both the particles the same size. In other words, they can be dispersed evenly. By using a homogenizer, substances that cannot be mixed normally can be mixed neatly, stabilizing the quality.

Based on our extensive experience, we will select and propose the optimal homogenizer to meet your needs.

The moment the vacuum bubbles burst or collapse in the liquid, a large shock wave is generated, generating large turbulence in the liquid, causing the particles in the liquid to be torn apart or collide with each other, resulting in atomization.

Features:

Disperses materials "without damage" and "without contamination." We have a wide variety of models available for research and development, corporate laboratory development, and mass production. Special specifications such as high density, high viscosity, and explosion-proof can also be customized.