・Jet mill

(Features)

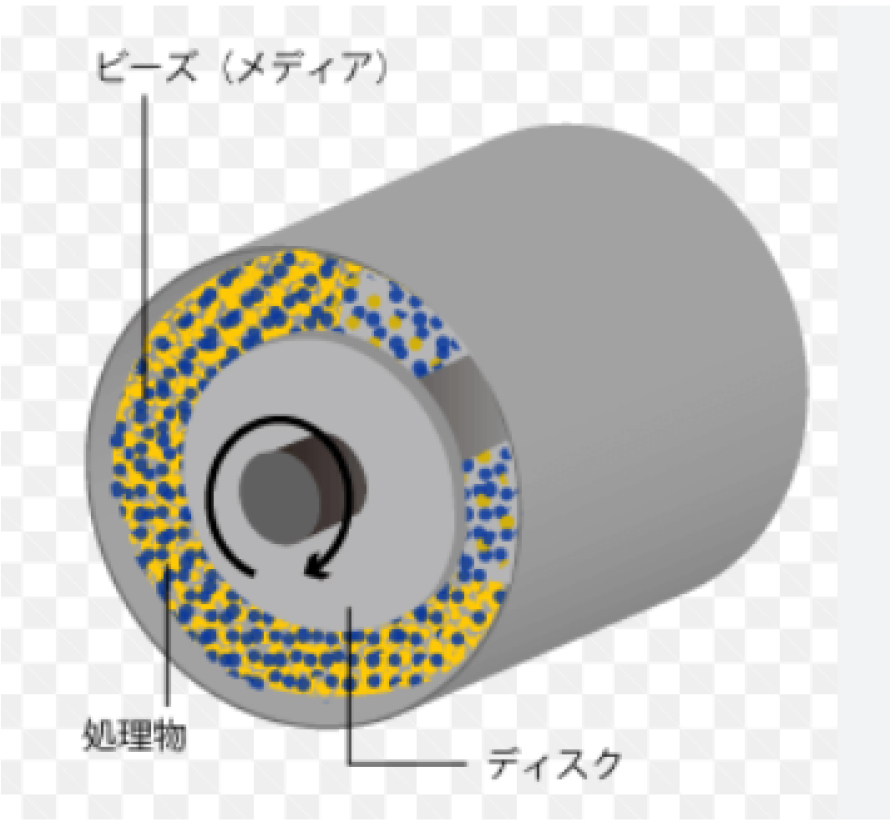

A jet mill is a method of finely pulverizing powder using the force of high-speed accelerated gas (usually compressed air or nitrogen gas). Specifically, the gas rotates at high speed inside the jet mill, providing high impact force to the material to transform it into a powdered state.

Due to the impact force from the gas jet, a jet mill generates fine particles uniformly. The narrow particle size distribution allows for obtaining electrode materials of uniform quality.

Furthermore, the low friction and heat generation in the pulverization process help maintain the material's quality. There is minimal risk of thermal degradation or changes in crystalline structure, ensuring that the characteristics of the finely pulverized electrode materials are not compromised. Being a sealed device, it minimizes the dispersion of dust and gas leakage during operation, improving safety in the working environment.

In addition to the above, various devices are employed for pulverization. Suggestions can include devices utilizing the expansion-contraction effect of bubbles (microbubbles) generated by