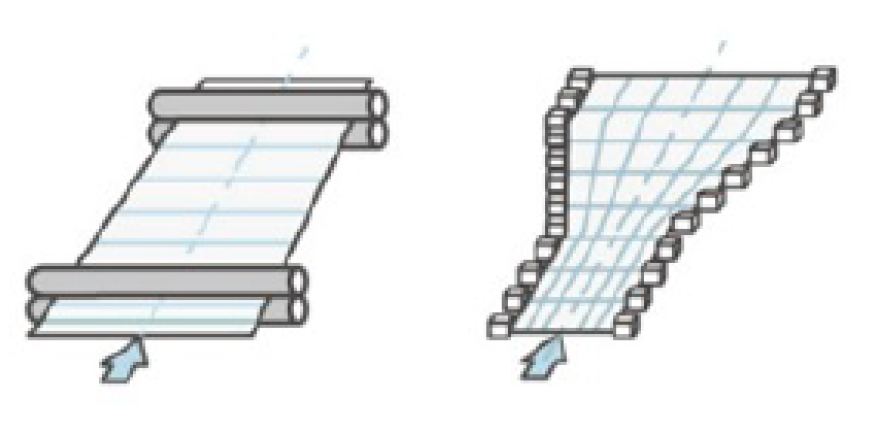

Stretch the film separately in vertical and horizontal directions.

In the stretching process of wet separators, the film formed through the extrusion/casting process is thinly stretched, and the amorphous areas where LP exists are expanded by successive or simultaneous biaxial stretching to form micropores.

The stretching process includes uniaxial stretching and biaxial stretching, and biaxial stretching is usually used in the separator manufacturing process.

Based on our extensive experience, we will select and propose most suitable stretching machine to meet your needs.

Stretch the film separately in vertical and horizontal directions.

【Machine Direction Orientation (MDO)】

Stretching is performed in longitudinal direction (film transport direction) by speed difference between front and rear nip rolls.

【Transverse Direction Orientation (TDO) 】

Stretching is performed in horizontal direction (perpendicular to the film transport direction) using tenter clips.

Advantages: Because of simple device structure, it is possible to achieve a wide range of specifications and low costs. Also easy to maintenance and has excellent productivity. Because vertical and horizontal mechanisms are independent, it is possible to make detailed settings for each item such as speed, magnification, and temperature, contributing to improved functionality and production by application.

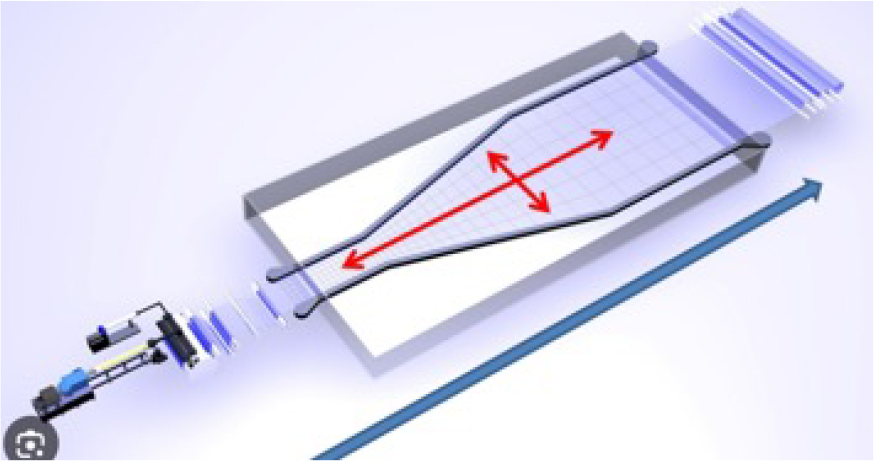

Stretch the film simultaneously

in vertical and horizontal directions.

This creates a uniformly oriented film.

Advantage: For resins that crystallize quickly, it is possible to uniformly stretch them in vertical and horizontal directions simultaneously before crystallization progresses.

Also possible to miniaturize the hole shape that serves as a passage for fluid. Ideal for customers who manufacture a small number of products.