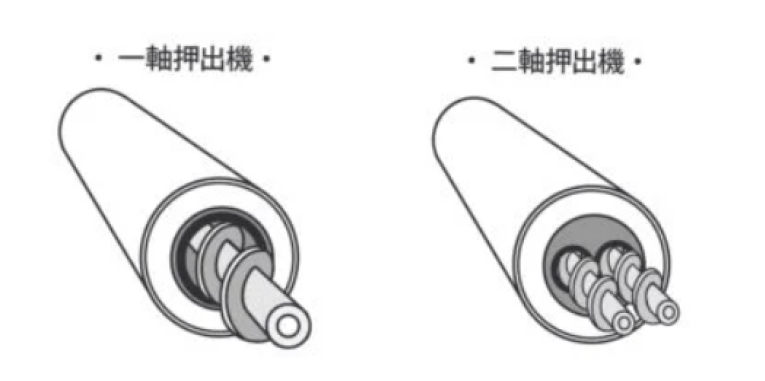

There are 2 types that simply use one screw (single-screw extruder) and types that use two screws for mixing (twin-screw extruder). Generally, twin screw extruder is adopted in separator film production.

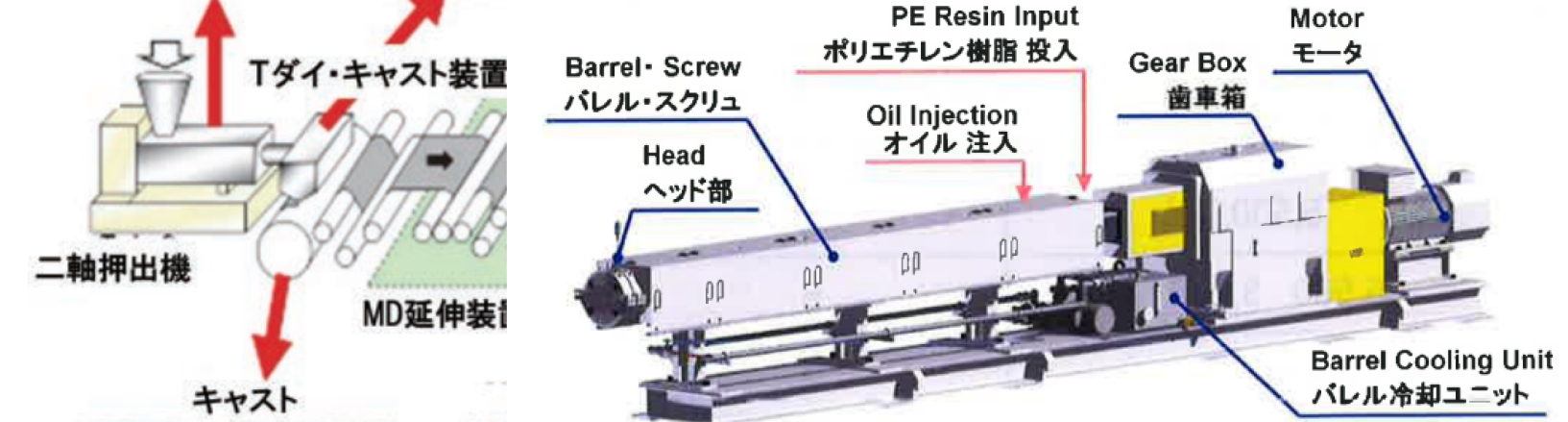

In the extrusion and casting process of wet separator production, the resin and solvent, which are the raw materials for the separator film supplied in the charging process, are plasticized and extruded from a die to form a continuous body with a predetermined cross-sectional shape. In order to achieve the extrusion volume that corresponds to the recent trend of wide width and high speed, we will select and propose the most suitable extrusion and casting equipment according to the needs of customers based on our extensive experience.

There are 2 types that simply use one screw (single-screw extruder) and types that use two screws for mixing (twin-screw extruder). Generally, twin screw extruder is adopted in separator film production.

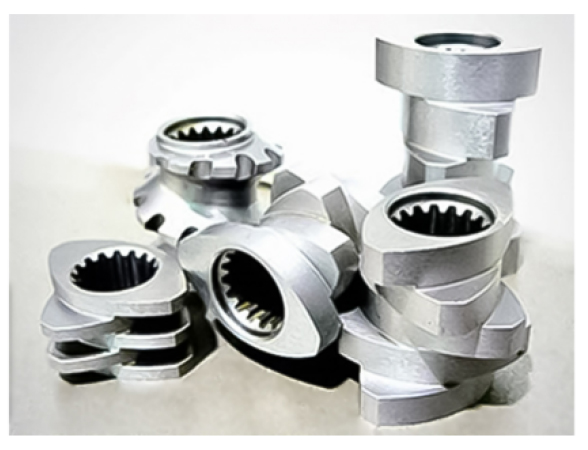

The resin is melted and kneaded using two screws inside the cylinder. Multiple resins and additives can be dispersed more homogeneously, and the screw configuration can be changed depending on the purpose.

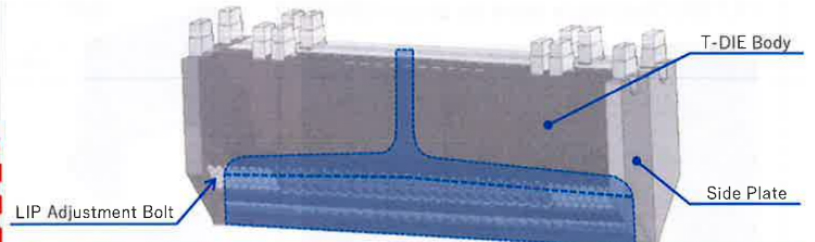

In microporous film formation, not only the shape of the T-die and the discharge rate, but also the temperature control of the melted and plasticized resin are important points.